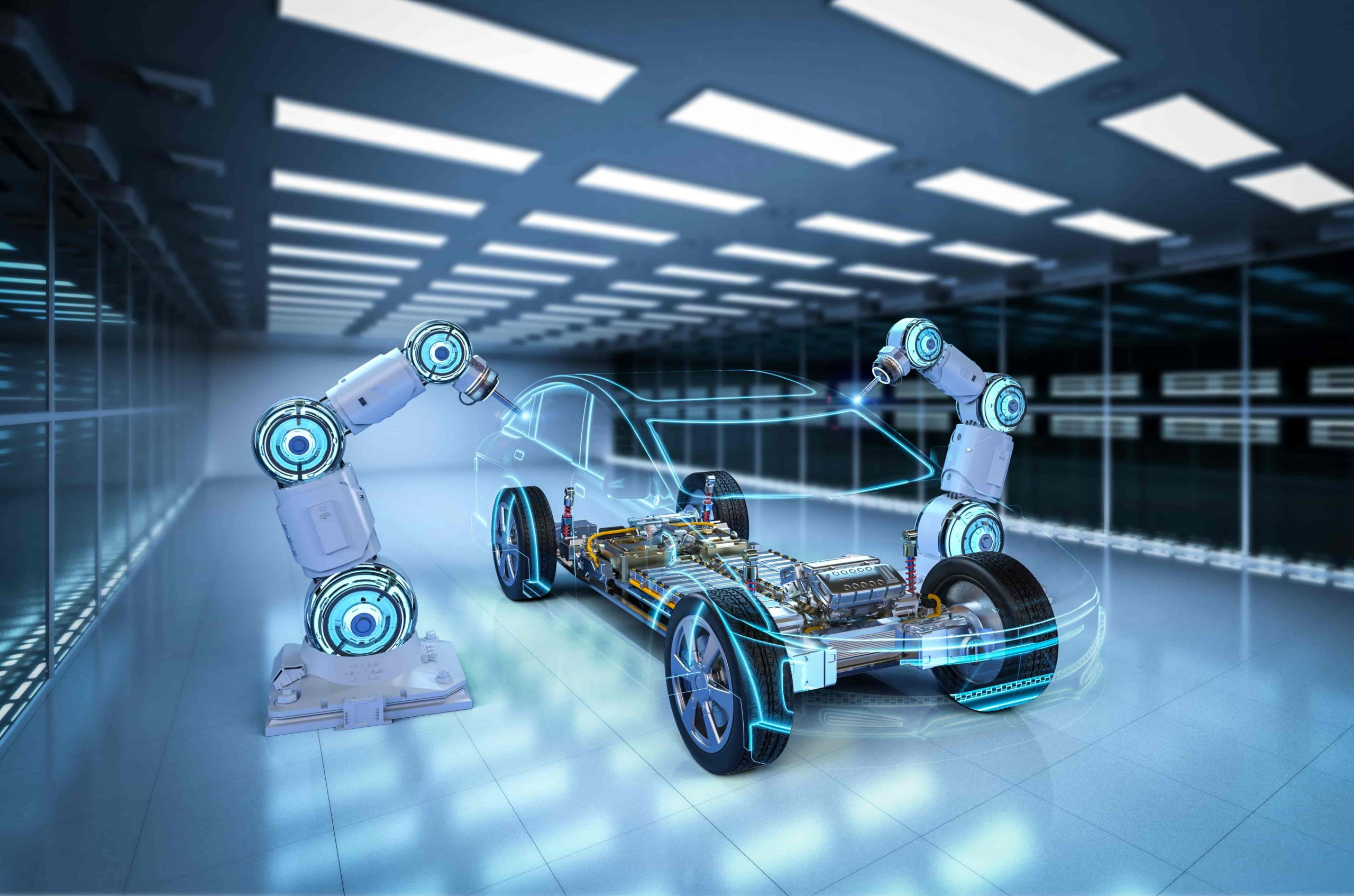

Virtual Validation

Allygrow has proven expertise in ensuring the reliability of any vehicle whether 2W, 3W, PV or CV using our simulation that you can trust! We’re heading towards ZERO Prototype! With Virtual Validation acting as the catalyst for accelerating product development, you can integrate and build your next vehicle 100% as planned, and achieve desired ROI. With our demonstrated capabilities, we have reduced physical prototyping at system level for many global automotive companies.

NVH

Driving comfort relies on occupants’ experience of noise, vibration, and harshness, especially in electric vehicles where silence is expected. With our optimization technologies and expertise, we assist in design optimization, reducing development time. Our simulations consider physical effects, real-world variability, and subjective experiences of noise and vibration, ensuring reliable predictions and minimizing costly design changes.

- Kinematics & Compliance (K&C) Simulation

- Ride & Handling

- Powertrain NVH

- Mount Optimization

Durability

Building durable products reduces warranty costs and increases reliability. Fatigue analysis is crucial for understanding product durability. Allygrow employs response analysis and random vibrations for component and vehicle-level analysis, estimating fatigue life and warranty costs effectively.

- Static

- MBD – MBD (Multi-Body Dynamics) Simulation

- Non-Linear

- Seating systems

Crash

Allygrow offers crash services to enhance vehicle safety and performance. We evaluate safety performance in real-world conditions, reducing development time. Our simulations optimize component designs for impacts and forces involved in collisions. By prioritizing occupant safety and offering accident reconstruction, we inform safer vehicle designs.

- Vehicle Crash

- Impact

- Occupant Safety

- Rollover

- Accident Reconstruct

CFD

Leverage our thermal simulation expertise to understand your product’s thermal characteristics and optimize performance. We offer comprehensive thermal management solutions for all automotive segments, including commercial/passenger vehicles and two/three-wheelers. Trust us to tailor your thermal management solution for optimal results. Benefit from our best-in-class capabilities in thermal simulation.

- Under-hood

- External

- Climate Control

- Powertrain

- Battery Thermal

Forging Simulation

Model and analyse the forging process of metal parts to optimize the forging process, predict the final product properties, and reduce the need for physical prototypes and testing.

- Special Forming Projects

- Value Engineering

- Cycle Time Reduction

- Quality Improvement

Injection Moulding

designing, developing, and optimizing the injection moulding process for plastic parts with aim to improve the efficiency, quality, and consistency of the injection moulding process, while reducing waste and cycle time.

- Product Design Validation

- Value Added Engineering

- Optimization- Product / Mould / Process

- Light-weighting

- Mould Design Validation

Embedded Systems

Our embedded systems expertise spans diverse industries delivering solutions driving technological progress. As a trusted engineering partner, we collaborate with businesses to address critical challenges, optimizing product development lifecycles and accelerating time-to-market for new technologies. With a wide experience across multiple sectors, we cater to a wide array of embedded systems applications, integrating with various hardware and software components.

Infotainment

- UX/ UI design

- HMI design

- Middle wave development

- Legacy migration

- Android QNX, ROS, iOS-based system

Body Control

- PEPS as a solution

- Bluetooth based door access system

- Automated wipers and lighting systems

- Electronics steering lock controls

- Automated seat adjustments

ADAS & Safety

- Software defined vehicle solutions

- Applications software solution development

- SIL, MIL, PIL testing

- Verification and validation

- Python, C, C++ based software development

- Object detections and cruise control software

- ALAKAS, power steering, smart cruise control algorithms & simulations

Telematics & In-vehicle Network

- Automotive protocols software development

- Drivers CAN, Fd, LIN, MOST, Flex ray protocols

- Domain controllers design & development

- DSRC solutions

- FOTA as an after-market solutions

Electrification

Vehicle Systems - Mechanical

- Body Assembly

- Frame Assembly

- Packaging of EV systems / sub-systems / components

- Feasibility Checks

- DMU Check / Clash Analysis

- Frame Design / Adaptation

- Virtual Validation

Vehicle Systems – Electrical

- Wiring Harness

- Embedded Systems

- EV peripheral system study

- EV peripheral system integration with core EV systems

- HIL / SIL / MIL Checks

Battery Thermal Management

Allygrow offers a comprehensive portfolio of cooling systems tailored for all types of electric propulsion (rechargeable hybrids and all-electric vehicles). Advanced simulation capability not only provides macro-level flow around the battery but also thermal validation of electronic BMS circuits. Our thermal management expertise in external and internal flow simulation in the battery compartment allows us to deliver solutions for battery load calculation and battery positioning.

- Cell Level Electro-Thermal Validation

- Battery Pack Level Electro

- Battery Pack Cooling Performance Evaluation

- Internal and External Short Circuit Treatment

- Battery Pack Thermal Management

Integrated Battery System Validation

In electric vehicles (EVs) or hybrid electric vehicles (HEVs), the battery packs must be consistently monitored and managed to ensure the safety, efficiency, and reliability of the entire electric vehicle system. Allygrow offers suitable and efficient validation of vehicle battery systems .

- Regulatory Compliance

- Modal Analysis

- Rechargeable Energy Storage System (RESS) Level

- Vehicle Level

Plant Automation/IoT

For maximizing operational efficiencies, reducing manual dependence, and optimizing the processes, industries across the world are relying on artificial intelligence, machine learning, data analytics and IOT. Extensive research and investment are going into these technologies to develop Smart Products and Smart Factories which produce them.

Allygrow has a dedicated team specialized in these future-ready technologies. Coupled with the domain expertise of product design, development and various manufacturing processes and systems, we have created a niche for ourselves. Our team can support design and integration of technologies like AI/ML and IOT in brownfield and greenfield setups to deliver state-of-the-art products and manufacturing systems.

Allygrow solutions in this space enable customers to add value to their products and operations and moving up the value chain in the ever-demanding market.

eVision

AllyGrow’s eVision employs computer vision technology with deep learning neural networks for accurate and versatile manufacturing processes. It captures and analyzes product images, enabling tasks like assembly verification, defect identification, counting, sorting, and non-contact measurement. eVision accommodates specific requirements, including tolerances, lighting conditions, and reflective surfaces.

eSense

Allygrow’s eSense solution enables data extraction and analysis from machine controllers, integrating existing plants into Industry 4.0+. With notable features like cloud agnosticism, data acquisition from existing machines, remote configuration, and predictive maintenance capabilities, eSense optimizes data utilization and decision-making. It also provides real-time access to key metrics, custom monitoring dashboards, and the ability to trigger automated enterprise actions.

Consultancy

Preparing for Industry 4.0+ compliant Smart factories is a complex endeavor. Allygrow offers consulting services to help manufacturers navigate this journey. Our holistic approach focuses on core areas such as Products and Services, Manufacturing and Operations, Strategy and Organization, Supply Chain, and Business Model & Legal Considerations. We provide services such as studying existing processes, developing implementation strategies, conducting Proof of Concept (PoC) projects, and guiding the selection of appropriate hardware and software for specific solutions.

Paperless Factory Solutions

AllyGrow’s Paperless Factory Solution It enables proactive issue forecasting in manufacturing, with easy access to technical information. It improves machine performance checks, maintenance record updates, knowledge access for new recruits, and reduces handover times. The application includes features like QR code scanning, user access control, and file upload/edit functionality. It offers on-premise data access for machine info, product info, procedures, maintenance records, troubleshooting guides, safety guides, and CAD data.

Geospatial & Enterprise engineering solutions for utilities, infrastructure & more

Industries We Serve

Featured Solutions

Head quarters

India

4A, Ground floor, IT8-Qubix Business Park SEZ, Blue Ridge, Phase 1, Hinjewadi, Pune – 411057,

Maharashtra, India.

North America

691 N Squirrel Road,

Auburn Hills, MI 48326,

United States

Europe

Allygrow Technologies GmbH,

Am Seedamm 44

60489 Frankfurt Main,

Germany

Other Locations

India - Bengaluru

Rachi Building, No 4085A, 5th C Main,

K. R. Road, Banashankari - 2nd stage,

Bengaluru - 560070

Karnataka, India

UK

AllyGrow Technologies UK Ltd.

Dunwoody House, 396 Kenton Road,

Harrow, Middlesex HA3 9DH