Styling

We interpret the functional aspect of design, creating forms and volumes that meet production needs. We accompany you from visionary concept design to product design and perfect Class A surface data

Benchmarking

Identify trends and best practices for ideas and inspiration to create unique designs

Style Definitions

Creating and defining the look, feel, and appearance of a vehicle through sketches, renderings, and 3D models

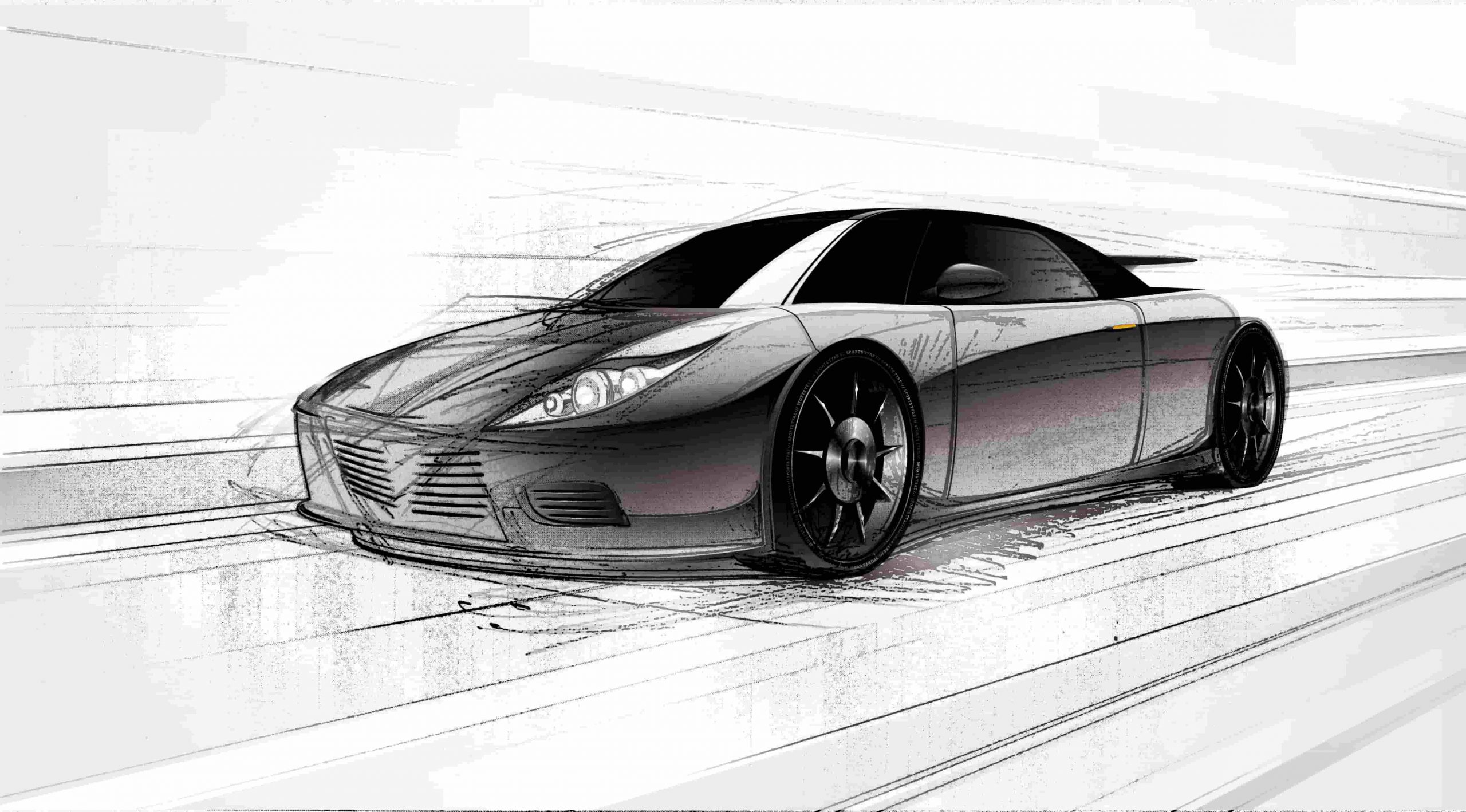

Sketching

Quickly explore various design options, refine ideas, and communicate the design intent to other stakeholders, before moving into more detailed design stages through a collection of visual cues sufficient to suggest the design

Rendering

Visualize the design with realistic interactions of lights, shadows, reflections, and materials across the surfaces for a more creative control over the appearance

Regulatory Compliance

Implementing modern tools to ensure regulatory compliance, and to meet functional safety standards.

Concepts

Concept development drives the definition and creation of a product. At Allygrow, we lead the convergence between the customer’s needs and the ideal technical solution to satisfy the product’s performances including ergonomics, safety, and user experience.

Concept Definitions

Aligning the overall appearance, functionality, features & technology to clearly communicate the vision for the product and establish a basis for further design and development.

Engineering Feasibility Checks

Evaluation & refinement of technical aspects of the vehicle design for practical & feasible production.

B Surface Development

Creation of design proposals and prototypes that demonstrate the potential appearance of a vehicle. Ensuring a cohesive and appealing design, both inside and out to create a visually appealing and functional product

Ergonomic Checks

Evaluating impact of interior and exterior design of the vehicle on the user to ensure a comfortable drive & ride experience. It involves analysing the various components, controls, and interfaces from the operator’s perspective and ensuring that they are well-placed, easily accessible, easily operable, and intuitive to use.

Fixing Strategy

Develop a feasible, scalable production & introduction plan through optimized & well-designed fixing strategy.

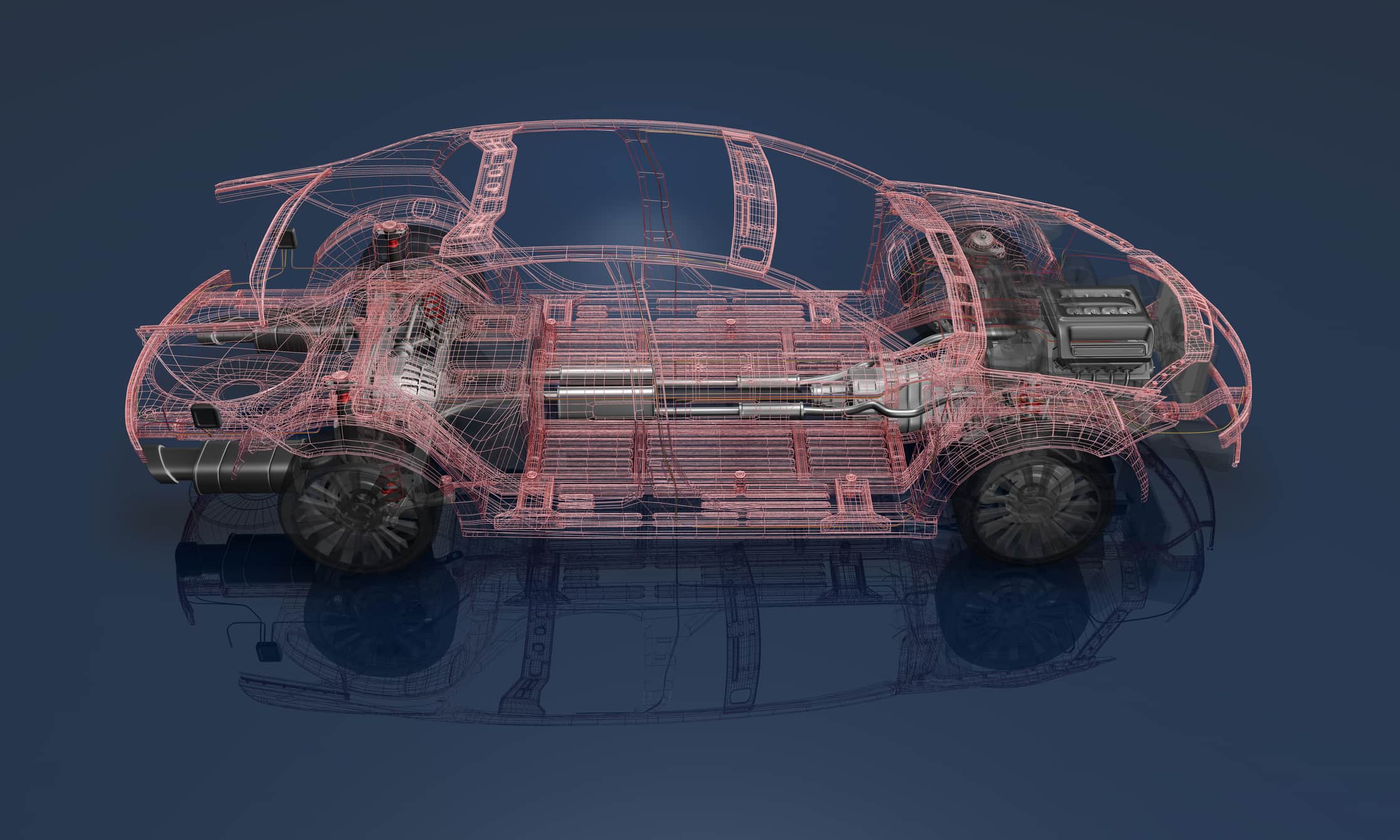

Feasibility

Allygrow feasibility analysis coordinates innovative designs with vehicle-specific characteristics. Our feasibility analyses enable product developers and engineers as well as process planners and die-face engineers obtain better part design, increased initial quality as well as reliable long-term behaviour. The feasibility analysis makes it possible to not only reduce development and manufacturing costs, but also to shorten the time to market.

A Surface Check

Inspection and verification of the exterior body surfaces of a concept or production vehicle to ensure that the exterior body panel meets the desired aesthetic, regulatory, dimensional and functional requirements

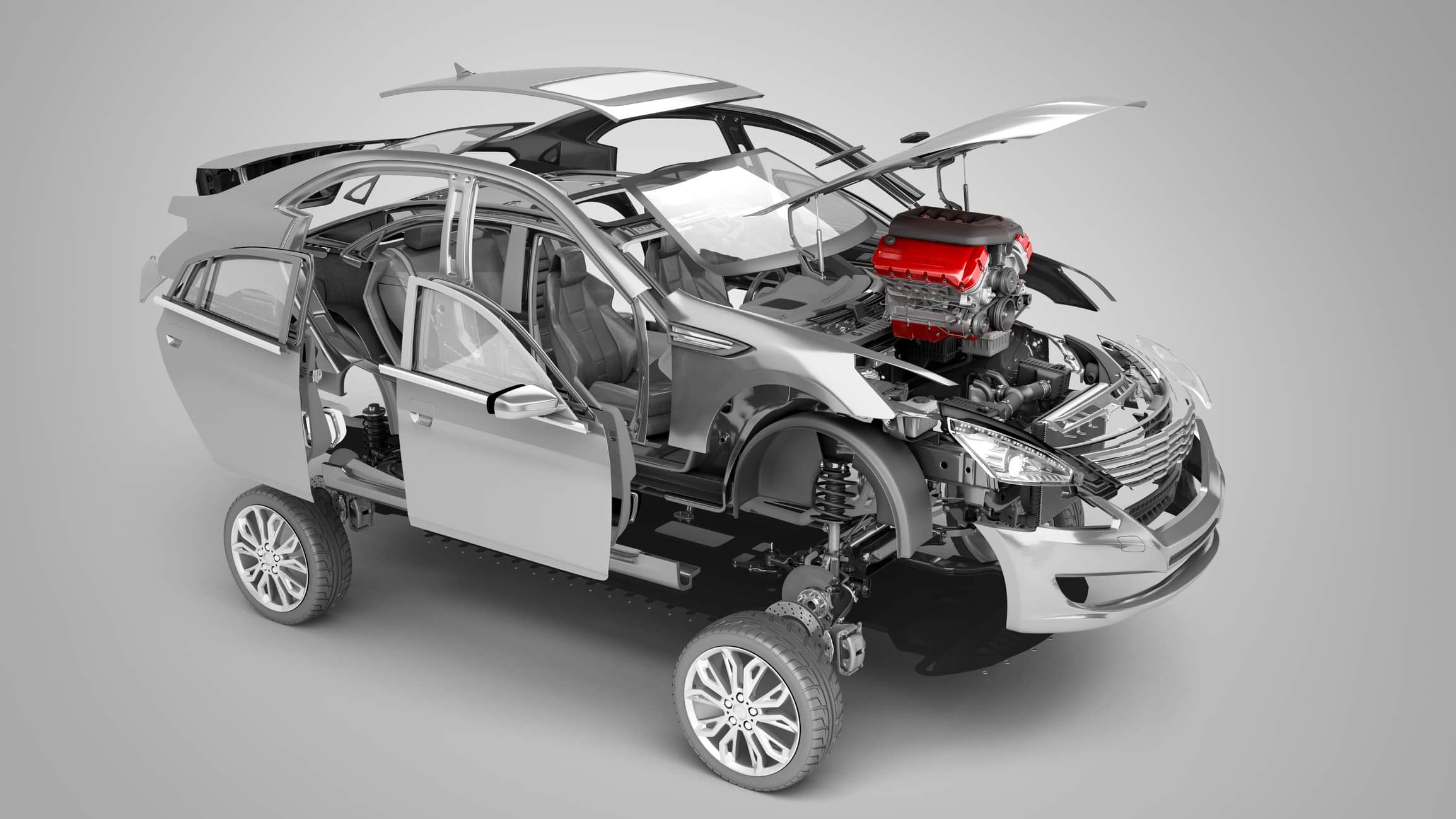

Packaging Studies

Determine the best layout and arrangement of components and systems within the vehicle to meet performance, safety, and functional requirements while optimizing the use of available space. This also includes space-claim studies for future variants & options.

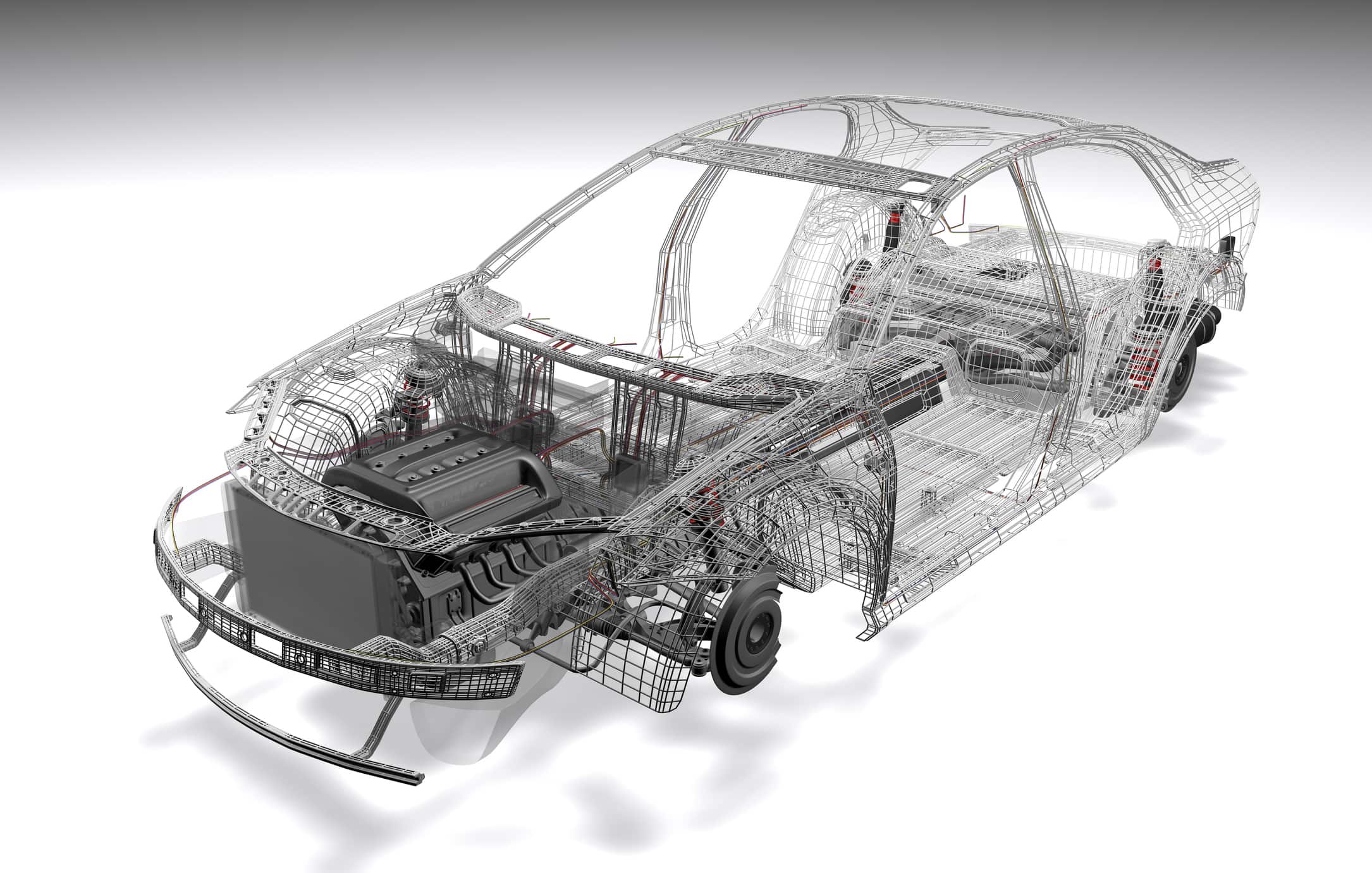

Digital Mock-Up (DMU)

3D digital model of the entire vehicle that can be used to simulate and evaluate various aspects of the design and engineering, such as packaging, manufacturing, validation of assembly processes & serviceability.

Master and feasibility section creation

Creating a master model or blueprint for the vehicle, It defines the overall shape, size, and geometry of the vehicle and is used to establish the design direction and target specifications, along with feasibility studies

Regulatory, Performance, and Safety (RPS) Check

Evaluate vehicle design against specific regulatory and safety standards, as well as any performance requirements set by the OEM.

Fit Function Requirement Check

Ensure that the vehicle is designed in a way that can be manufactured, assembled, and operated as intended, and meets the performance requirements set by the OEM.

Design & Validation

By validating products and product features at an early stage, development periods are optimized and development costs reduced. Our experts take over responsibility for the functional design of components, systems and complete vehicles.

Engineering Design (DFM, DFA, DFS checks)

Ensure that the final design of a vehicle is both cost-effective and practical to manufacture and maintain.

Geometric Dimensioning and Tolerancing (GD&T) Plan

Ensure that the physical parts match the design intent, reduce manufacturing variability, and improve the overall quality of the product.

Virtual Validation

Improve the design, identify risks & failure modes, and make informed decisions about the development of the vehicle.

Engineering Proto Release

Preparing and releasing a physical prototype of a vehicle for testing, validation, and evaluation purposes before production.

CAD & ECM

We create, modify, analyze, and optimize product design, to drive innovation, optimize costs and get incredible new products.

Pre-Series Development

Minimize production issues and ensure a smooth start of mass production. Automotive pre-series development is the process of testing and validating a vehicle before its mass production. Thanks to our expertise in complete vehicle development, we can flexibly support all necessary development steps and processes even in this early phase.

2D & 3D tolerance analysis

Analyze the dimensions and tolerances of parts and components in a vehicle to ensure they meet the required specifications, before the start of the actual production.

Pre-Series Manufacturing

Testing and validation of manufacturing processes before starting full-scale production.

Pre-Production Support

Preparation and support for the start of mass production of a vehicle, usually involving activities such as tooling release, manufacturing setup, and process optimization.

Plant Engineering

In the capital-intensive and technically complex world of automotive manufacturing, global brands must balance quality, risk, and cost with efficiency and safety — while simultaneously striving for innovation. We help integrate people, process, and technology to improve business results.

Plant Layout

Optimize the use of available space, reduce material handling costs, increase efficiency, and provide a safe and efficient working environment.

Processing and Cycle Time Studies

Systematic analysis of the operations and processes in a manufacturing or production environment to identify areas of improvement and optimize the time required to complete each task.

Process Validation

Evaluate the manufacturing equipment, procedures, and processes to identify and correct any issues that could affect product quality and consistency.

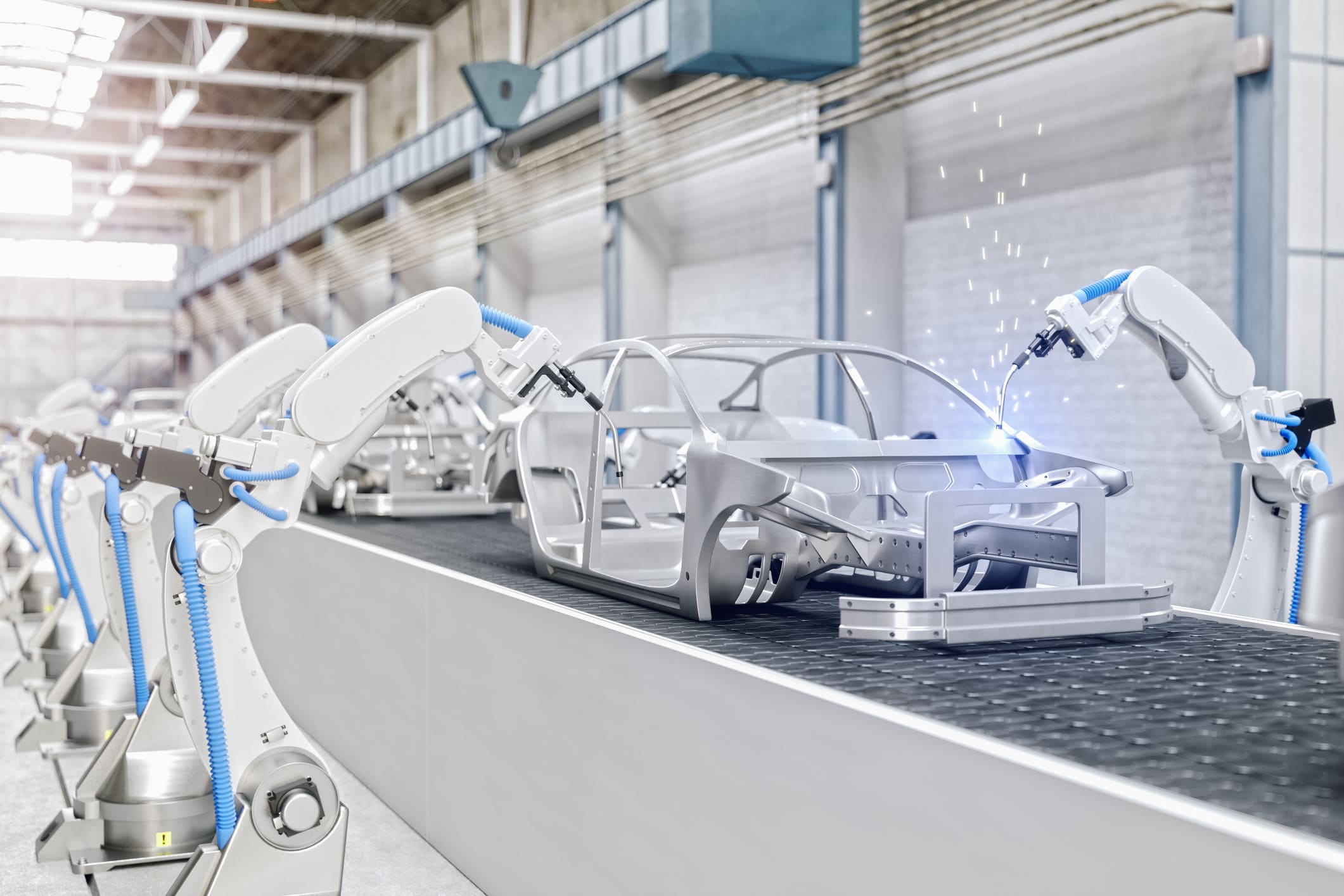

Manufacturing Engineering

Assembly automation is the strategic integration of advanced technology within assembly processes. Allygrow has extensive experience in a range of assembly solutions, from stand-alone operator-assisted stations to larger, fully automated, robotic assembly lines.

Assembly Line Design and Simulation

Design, evaluate and optimize the assembly processes in a manufacturing facility to optimize the flow of materials and information, minimize bottlenecks, reduce cycle time, and ensure efficient utilization of resources.

Detailing

Detailed technical drawings and specifications for the manufacturing process of a product including drawings for individual parts, assembly drawings, process flow diagrams, and manufacturing process plans.

BOM

Provide a comprehensive and up-to-date guide for procurement, production, and quality control during the manufacturing process.

Build and Installation Support

Ensure that the manufacturing facilities and processes are installed, qualified and capable of producing products that meet the specified quality, cost and delivery requirements.

Industrial Consultancy

AllyGrow Technologies’ Industry Consultancy services focus on driving manufacturing excellence. Our tailored advisory solutions empower clients to achieve and sustain peak performance across critical business dimensions: Customer, Internal, Financial, and Growth Perspective.

At AllyGrow, we believe in a bespoke approach, tailoring our methodology to each client’s unique business ecosystem. Our expert team guides clients on a continual journey towards excellence, anchored by our comprehensive consulting framework – EDIFY.

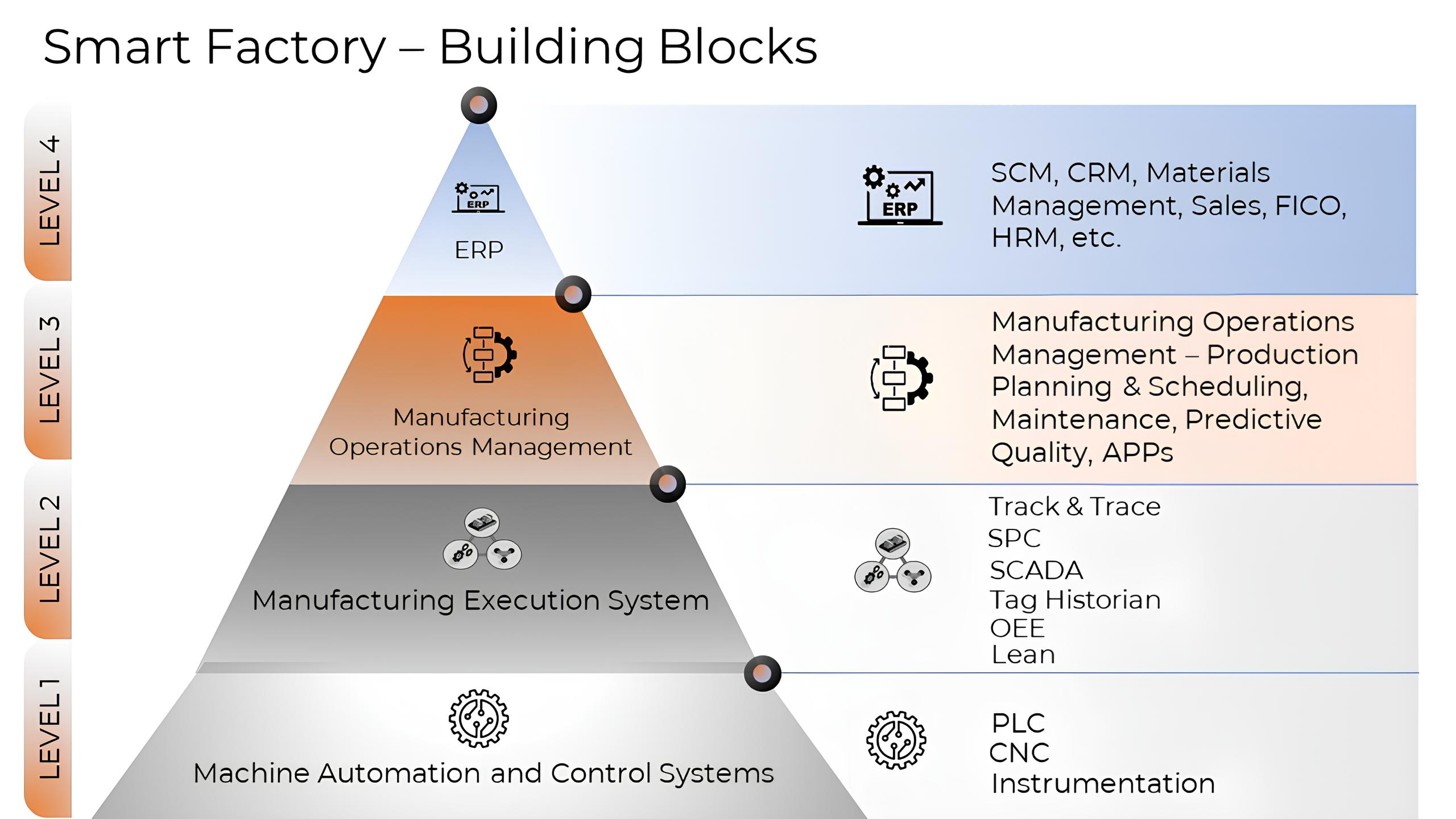

Our digitization advisory services pave the way for clients to develop a roadmap for an integration across all layers of their organization. From the shop floor to business operations, we evaluate technological interventions to establish Industry 4.0 enabled Smart Manufacturing, providing business benefits.

Engage

Diagnosis

Improvement Solutions

Facilitate

Institutionalize

Geospatial & Enterprise engineering solutions for utilities, infrastructure & more

Passion.Pace.Perfection

Satisfied Customers

Project Hours

Industries We Serve

Featured Solutions

Head quarters

India

4A, Ground floor, IT8-Qubix Business Park SEZ, Blue Ridge, Phase 1, Hinjewadi, Pune – 411057,

Maharashtra, India.

North America

691 N Squirrel Road,

Auburn Hills, MI 48326,

United States

Europe

Allygrow Technologies GmbH,

Am Seedamm 44

60489 Frankfurt Main,

Germany

Other Locations

India - Bengaluru

Rachi Building, No 4085A, 5th C Main,

K. R. Road, Banashankari - 2nd stage,

Bengaluru - 560070

Karnataka, India

UK

AllyGrow Technologies UK Ltd.

Dunwoody House, 396 Kenton Road,

Harrow, Middlesex HA3 9DH